Daily Management in Healthcare: Embedding Accountability

“The idea is: let’s fix it in the moment.”

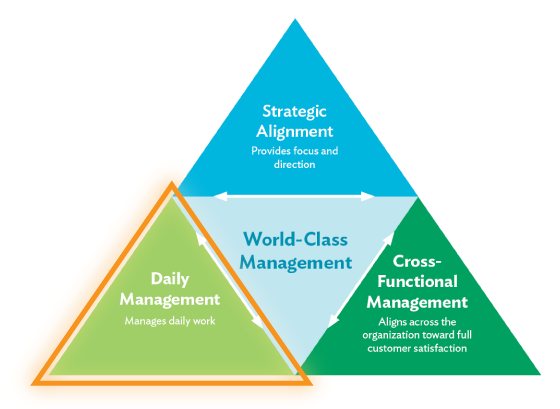

World-Class Management, a foundational management system and pillar of the Virginia Mason Production System® (VMPS) has three components:

- Strategic Alignment, which provides focus, direction and alignment within the organization;

- Cross-Functional Management, which aligns across the organization toward full customer satisfaction; and

- Daily Management, which makes daily work visible and is essentially a form of standard work for leaders.

Daily management is a critical component for sustaining improvement

Virginia Mason achieved striking improvements over the years due in large measure to five-day Rapid Process Improvement Workshops (RPIWs). While highly productive, these sessions are also time-consuming, requiring substantial preparation by the teams before the workshops even begin. “Our vision is to go from firefighting to creating capacity so you can see what is coming down the pike,” says Linda Hebish, previously an administrative director at Virginia Mason’s Kaizen Promotion Office. “With daily management, we want to determine how we did today and how can we do better tomorrow.”

“We also do a lot of two-day events and now we are saying, with daily management, the idea is this: Let’s fix it in the moment,” says Hebish.

Since adapting the Toyota Production System to healthcare, Virginia Mason teams have continued seeking ways to improve care delivery by learning from industries outside healthcare. For example, Hebish learned valuable lessons during gatherings of the Association for Manufacturing Excellence. “In 2010, we were not moving as fast as we would have liked,” she says. “We had been to Japan multiple times, gone to different manufacturing conferences, and one thing we would always see in manufacturing settings is production boards and genba walks by leaders at all levels. We were seeing it all the time, yet we weren’t doing it here.”

After extensive internal discussion and study, including reading Creating a Lean Culture: Tools to Sustain Lean Conversions, by organizational psychologist David Mann, Virginia Mason leadership decided to implement the changes required that would support daily management.

“Daily management — which is really leadership standard work — is considered by many people in manufacturing to be a game-changer and I believe it’s true,” Hebish says. “What better role model for frontline workers than leaders being present where the work is done — teaching, guiding and coaching. Leaders are on the genba to coach, mentor and improve daily work by reducing waste.”

She describes five key elements of daily management:

Creating a Production Board

Hebish relates a simple example from the clinic. “Let’s say there is a group with five doctors and the board shows that Dr. A has six appointments in the morning, while Drs. B and C each have 10 appointments. The question is how to get Dr. A’s schedule in sync with the others.”

First is creating a production board. The boards serve as a quick, visual display of what a particular department produces in its value stream and shows whether the department at any given moment is in a normal or abnormal condition. Boards vary significantly from one department to the next.

When the board displays such an imbalance, team members immediately let the call center know that Dr. A has openings. The board also provides concise information about the team — who is sick, on vacation or working on an RPIW, for instance. It lists the care nurse for the team, as well as the overflow physician if all doctors get fully booked.

The board also displays indirect care — the emails, paperwork and phone calls that flow into physicians throughout the day. In past analyses, Virginia Mason physicians had noted, on average, that primary care physicians received upwards of 60 pieces of indirect care daily and much of that work could be handled by a medical assistant (MA) or nurse. When indirect care is handled in flow by MAs and nurses — and physicians when necessary — it makes a significant difference in keeping the physician in flow and on time throughout the day, even as it allows doctors more time with patients and less on indirect care.

One of the most interesting things about daily management is that teams voluntarily fill in for one another when needed. At the beginning of each shift, the team leader — usually the supervisor — reviews the board with the nurses, MAs and physicians when available.

“When a team is behind, they might need an MA to help with setup for the next patient or they might need a nurse to counsel a patient over the phone,” says Hebish. “It is very important for us to understand what normal status is and what to do when we are in abnormal status. We have struggled with that; it is easy to create a board but not so easy to create the action you take as a result of what the board is telling you.”

Throughout the day the board is updated. For example, when the number of pieces of indirect care for a physician exceeds 18, that fact is noted in red on the board, and nurses and MAs step forward from other teams to reduce the number and help the physician get back in flow.

Daily Accountability

The second element of daily management is daily accountability. This is accomplished by having the team huddle around the board and set their plans for the day, making adjustments in terms of personnel or scheduling when necessary. It is about knowing the reality of the moment — what do you need that you do not have — and filling gaps.

“With the daily huddles what we’ve found is that once the leader does it a few times, he or she will hand it off to the staff, and the leader then observes as frontline staff members go through the huddle process,” says Hebish. “It really helps create staff engagement and empowerment.”

Standard Work for Leaders

The third element of daily management is for the leader to create his or her own standard work and to make that work visible to team members. Some leaders do this with a board on their office door or posted somewhere centrally so any team member can readily see it. The leaders list will indicate his or her standard work for each day, week and month. “The closer you are as a leader to the frontlines, the more standard your work,” says Hebish.

This approach is impactful. Danna Priest, RN, in the Kaizen Promotion Office, made this observation from her time as an assistant nurse manager in medical telemetry: “I used to go home at the end of the day and think, ‘What did I even do today?’ Before using standard work for leaders, I felt like my day was spent putting out fires and reacting. Now I feel aligned with my team and vision, and it allows me to be proactive in meeting goals.”

Root-Cause Analysis

The fourth item within daily management is root-cause analysis, which involves teams getting at the root cause of any issues within their work areas to eliminate waste. Root-cause analysis helps team members capture those abnormal items and track them so they can feed into their kaizen — or, improvement — work. It is critical to spend time understanding the real problem by using a defined approach. Many issues can be solved in the moment, while others may require additional resources from upstream or downstream areas. These cross-functional issues can lead to an RPIW or other kaizen activity.

Cindy Rockfeld, previously an administrative director in ambulatory services, explains that root-cause analyses are particularly effective when applied to multifaceted challenges. When a physician says there are holes in the schedule, for example, root-cause analysis brings all stakeholders together to get at facts, not assumptions. “As a result,” she says, “we get different perspectives from different stakeholders. While the physician may say the hole in the schedule is due to lack of demand, the scheduler may say there are holes because the schedules are blocked. Getting the big picture of the root causes for a particular problem is powerful and enables the team to do better planning of the improvement work.’’

Observing the Frontline

The fifth item Linda refers to is going to the frontline where the work is being done (also known as genba walks). “It’s a prescribed routine where leaders walk the genba and not only look for accountability, but also work with and coach frontline team members. It is a teaching role that guides and empowers staff members,” she says.

“World-Class Management and daily management in particular are game-changers because you are embedding accountability throughout your leadership team at all levels,” Hebish says. “You are seeing in real time what your production is today.”

Originally published July 3, 2013, updated January 31, 2022