Why Is a Value Stream Map Important for Transforming Patient Care and Decreasing Costs?

A value stream map is a visual depiction of a process from a request for a product or services through delivery. At Virginia Mason, we depict this process not from the point of the view of our health care delivery team, but from the patient’s — or customer’s — view of the value and the flow of a process.

The value stream map is developed through direct observations at the place the work is done. In fact, it takes a lot of observations on the front lines to collect enough useful data to reflect the current state of the process.

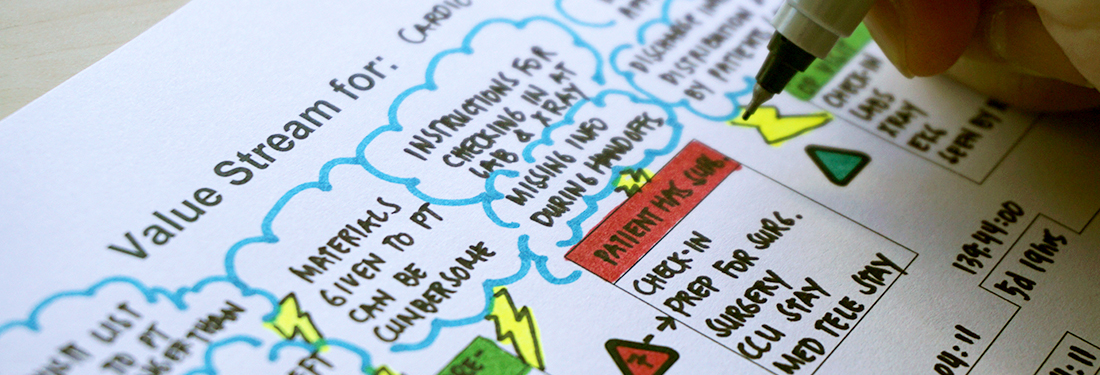

We use time as a measure of process health. The lead time (the time for the entire process), cycle times (time to complete one cycle of work) and wait times depicted on the value stream map help us identify opportunities for improvements. Images we refer to as cloudbursts (or kaizen bursts) depict the defects and waste we find in the process to make them obvious to others. And as we work to remove the waste and improve flow, we keep updating our map to capture the improvements.

What makes a value stream map an ideal improvement tool?

The value stream map helps us see waste and direct our improvement efforts. Without it, it would be difficult for us to analyze, understand and share with key stakeholders what was currently happening in our process flow. We’d be acting on assumptions, using subjective analysis to guide our improvement work.

Before creating a value stream map, many people think they know the problems with their team’s process. However, after they observe what’s happening on the front lines, collect and analyze the data, and complete the map, they might see that what they thought was their biggest problem was actually an issue with low occurrences. That’s why it’s so important to use an objective tool.

The goal is to identify all the problems and then to prioritize which problems to address first through kaizen planning.

Where the map is most useful

We use value stream maps for all of our improvement work to improve safety and build reliability into our processes throughout the medical center, including our hospital, our clinics, our supply chain and our corporate areas. They’ve helped us make significant improvements in early sepsis identification and intervention, patient falls, medication errors and so many other areas.

Because value stream maps depict the entire process, they help us see across functional boundaries. In our orthopedic value stream, for example, our leaders and team members from the orthopedic clinic, the operating room, and the hospital collaborated to smooth the flow and add value to the orthopedic patient’s experience. And when we had a really complicated and difficult problem to solve about how to consistently maintain an accurate patient medication list throughout our organization, we were able to use a value stream map to see the problems and work as a team to solve them.

“Using value stream maps helps us improve the performance of our processes. They also help us increase capacity by identifying waste so that more patients can move efficiently through our system. By helping us see and eliminate waste, they help make us a facile, adaptive organization — and it’s because we’re focusing on quality, not on cost.”

– Rosemary King

How the map helps enhance patient experience

Some people ask us how we know what’s most important to patients and what to write inside the cloudbursts in our value stream maps. We start by acknowledging that our assumptions about what our patients want may not be correct. Then we use a variety of innovative methods to find out what makes the most difference to them. We learn about our patients’ experiences by studying our patient satisfaction data reports, by talking to patients directly during their stay with us, by involving them as team members in our improvement events (especially our Rapid Process Improvement Events), and by directly observing them on the front lines. We also use experience-based design (EBD) methods, in which patients talk about their emotional response to a question such as “How did I feel when waiting for the procedure?”

How it promotes team engagement

The value stream map helps to engage our team members and connects them to the work. It also helps leaders connect the dots of their processes to our organizational goals.

Across the organization, our leaders ask staff members for their ideas to improve their work. We ask staff in our daily huddles; we ask them in our weekly PeopleLink meetings; we ask in emails and newsletters. Most people are excited to contribute, and some need coaching and encouragement. Everyone has a voice about how to improve their work and provide a better experience for our patients.

And at Virginia Mason, we recognize people for the ideas that make it through execution. We share the ideas through our Everyday Lean Idea System, and we acknowledge ideas in staff performance reviews.

Value stream maps also help leaders across the organization work together to identify the flow issues upstream and downstream. Once the leaders understand the issues their patients and colleagues face in different departments, they can adjust their processes accordingly to improve the flow.

How it connects to cost

Using value stream maps helps us improve the performance of our processes. They also help us increase capacity by identifying waste so that more patients can move efficiently through our system. By helping us see and eliminate waste, they help make us a facile, adaptive organization — and it’s because we’re focusing on quality, not on cost.

Even more, the value stream maps expand everyone’s understanding. If patients have a delay in discharge because they’re waiting to go to a nursing facility, we can find out why. We can ask, “If we knew from the beginning that a patient might need post-surgery care in a nursing facility, what prevented us from creating a smooth process from the time he checked in for surgery?” We can then observe the process and populate the value stream map with data — writing down the problems inside the map’s cloudbursts — and then we can create, test and implement solutions. When patients aren’t delayed during discharge, the patient experience is better and the cost savings follow.

The end result

When we use a value stream map, people are no longer working in isolation. They’re working together like musicians in a symphony. Before long, everyone knows their parts, the process flows and the result is beautiful music. Every part adds value. And in our symphony, our employees work together better, our patients receive better care, and our efficiency and costs improve.